Beacon Machine Manufacturing Co.,ltd

Beacon Auto Repair BD101 Brake Disc Laser Semi-automatic Testing Machine

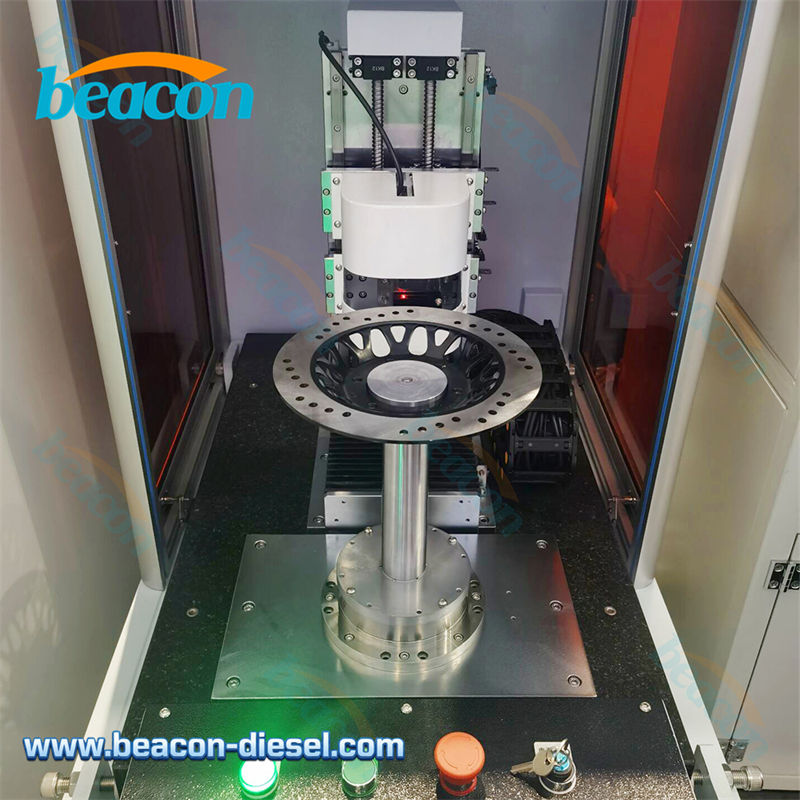

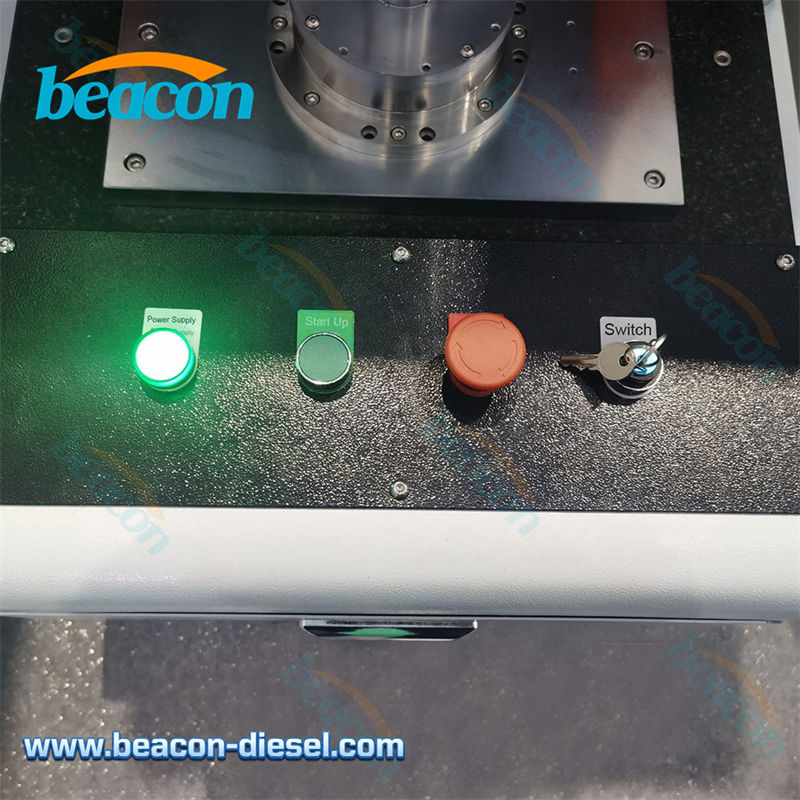

Optimize your quality control with the BD101 Brake Disc Laser Testing Machine. Featuring an air-floating spindle and high-precision sensors, it measures thickness variation (DTV) and runout in under 10 seconds with 0.0015mm accuracy.

Introduction

Value Proposition:

The BD101 is engineered to streamline the quality assurance process for brake disc manufacturers. By replacing manual checks with automated laser precision, this machine enables operators to verify critical geometric tolerances in seconds, significantly reducing production bottlenecks and ensuring strict compliance with automotive safety standards.

Key Features & Functions:

-

Superior Accuracy: Utilizes high-precision laser sensors with a measurement range of ±3.7mm and actual testing accuracy reaching ±0.94um.

-

Advanced Mechanics: Features a high-precision air-floating spindle (end face runout < 0.001mm) and Japanese THK linear guide rails driven by servo motors.

-

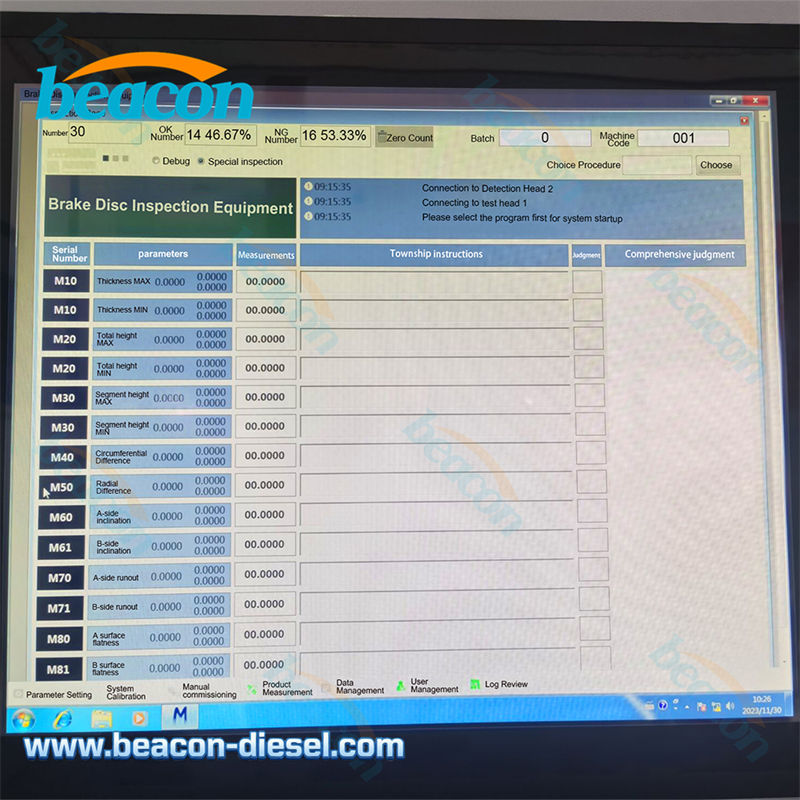

Smart Automation: Powered by a Taiwan Advantech industrial PC, the system automatically filters out groove interference, calculates defect rates, and saves all data.

-

Comprehensive Detection: Measures upper/lower surface runout, flatness, parallelism, plate thickness, and Disc Thickness Variation (DTV).

-

High Efficiency: Achieves a measurement rhythm of less than 10 seconds per piece. Suitable for workpieces ranging from φ100 to φ340mm.

parameter

| Item | Specification |

| Power Supply | AC220V ±10% |

| Environment | Machining workshop (free from strong seismic sources, dust, and magnetic interference) |

| Temperature | 5℃ — 40℃ |

| Gas Source | 0.5 ~ 0.7 Mpa |

*Test data from Beacon laboratory

Related products

Language

Language