Beacon Machine Manufacturing Co.,ltd

Common Faults and Maintenance of Diesel Engine Injectors in Construction Machinery

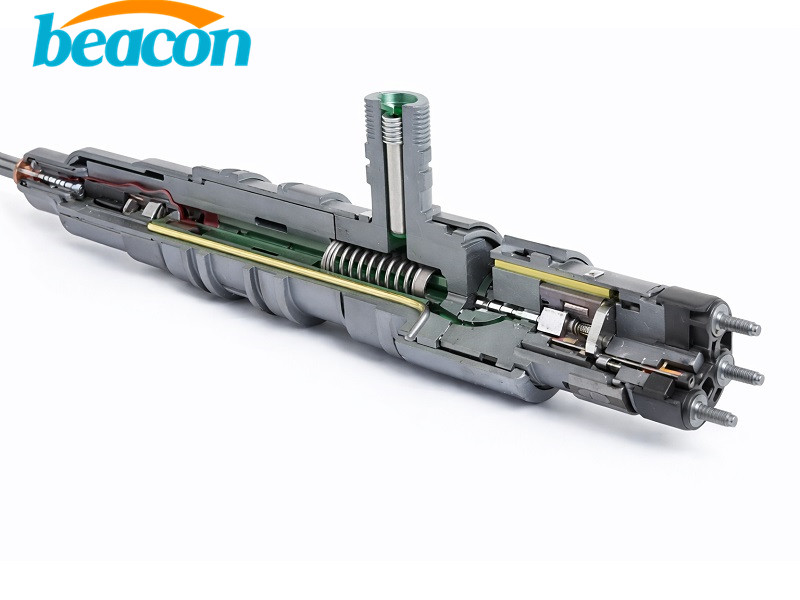

The diesel injector is a primary component of the diesel engine and is a high-precision part. During actual use, faults such as blockage, needle valve sticking, and seal failure often occur. These manifest as incomplete diesel combustion, leading to rising oil levels, dropping power, excessive carbon buildup in the cylinder, and aggravated wear. Therefore, whether the injector works properly directly affects the diesel engine's performance. Below is a simple analysis of troubleshooting common injector faults.

1. Leakage at the Injector and Cylinder Head Joint (Oil/Gas Leak)

If there is carbon buildup in the installation hole on the cylinder head, the copper washer is damaged, or if an asbestos plate or other materials are used to replace the copper washer, or if the washer thickness prevents the injector from extending correctly into the combustion chamber, it will cause poor heat dissipation and sealing failure, leading to leakage. When installing injectors, carbon deposits in the installation hole must be carefully removed. The copper washer must be flat and should not be replaced by asbestos or other materials to ensure heat dissipation and sealing.

Note: Install the washer with the concave side facing down. Tighten uniformly according to torque specifications, avoiding unilateral bias to prevent injector head deformation and leakage.

2. Needle Valve Sticking

Main causes of needle valve sticking:

(1) Improper installation causing local overheating and distortion.

(2) Lack of regular maintenance and cleaning, or improper pressure adjustment.

(3) Impurities or excessive water in the diesel fuel.

(4) Poor sealing of the needle valve cone, allowing combustion gas to enter and burn the mating surface.

(5) Excessive engine operating temperature.

If the needle sticks in the open position, the injected diesel cannot atomize, causing incomplete combustion and black smoke. Unburned fuel may wash oil off the cylinder wall, accelerating wear. If it sticks in the closed position, high pressure builds up, potentially damaging the pump plunger.

Repair: Stuck needles are not always scrapped. Soft objects (like wood) can remove carbon. Grinding with oil may restore it. If the needle cannot be pulled out, soak the nozzle in diesel, heat until boiling, and remove while hot. Clamp the nozzle in a vise (with copper protection) and pull/twist the needle out. If damaged, replace the needle valve assembly (nozzle). New nozzles should be boiled in diesel at 80-100°C to remove anti-rust oil before use. Avoid contact with hard objects during cleaning to prevent scratching the guide surface.

3. Injector Wear

Wear primarily occurs on the sealing face, spray hole, and needle valve guide.

Wear on the sealing face causes leaks and poor atomization. Repair by grinding with a small amount of grinding paste on the needle head cone. After grinding, clean and test performance. If it fails, replace the needle valve coupling.

Enlargement of spray holes leads to pressure drop and poor atomization. For multi-hole injectors, replace the nozzle coupling if wear is significant.

Wear on the guide face increases fuel return and lowers pressure. Replace the coupling if wear is severe.

4. Spray Hole Blockage

Main causes:

(1) Long-term idling causing semi or complete blockage by deposits.

(2) Solid impurities in fuel.

Blockage raises injection pump pressure and causes a knocking sound. To prevent this, filter fuel strictly and improve combustion.

Repair: Remove the injector. Use a steel wire or a specialized cleaning needle to clear the blockage. The wire should not extend more than 2mm to prevent breaking inside.

5. Injection Pressure Too High or Too Low

Too High: Sticking needle, spring tension too high, or clogged holes.

Too Low: Worn guide/seal, loose adjustment screw, or broken spring.

Incorrect pressure leads to unstable operation, power loss, and premature wear. Adjusting pressure too low increases fuel consumption and smoke; too high causes knocking and pump wear.

Regular fault analysis and maintenance can effectively reduce injector failure rates.

Related products

Language

Language