Beacon Machine Manufacturing Co.,ltd

Comprehensive Guide to Internal Lift Parameters: Delphi and CAT CR200 Common Rail Injectors

Internal Lift Parameter Definitions for Delphi and CAT Common Rail Injectors

I. Delphi Injectors

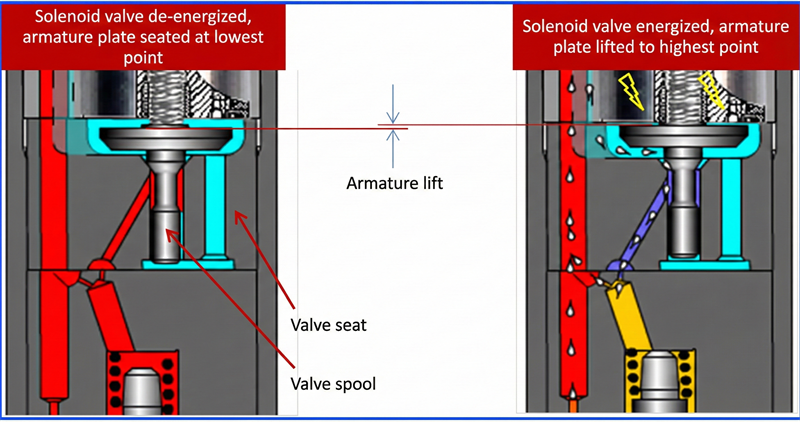

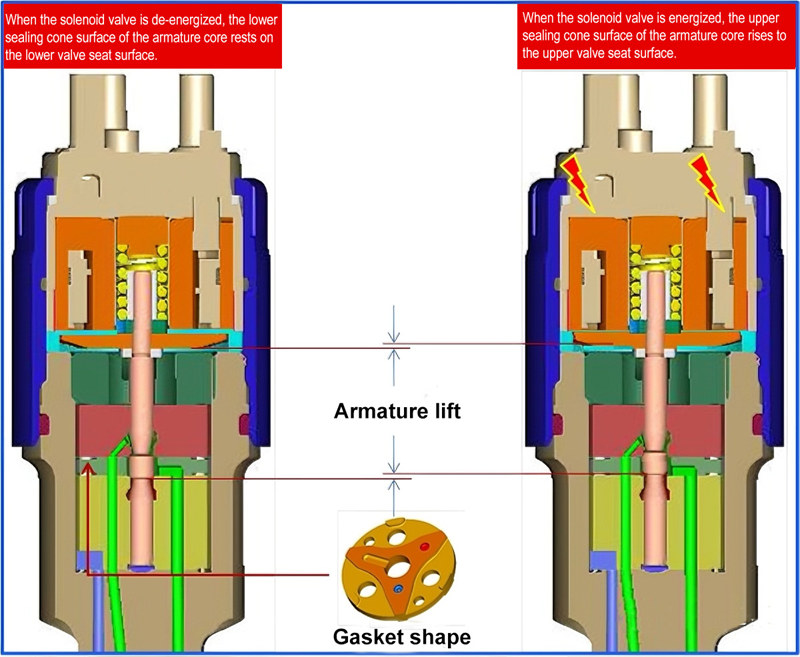

1. Armature Lift

-

Definition: The maximum distance the valve core can move during the injector's operation. The armature lift for Delphi common rail injectors is generally between 30~70 microns.

-

Schematic:

-

Adjustment Trend: The armature lift of a Delphi injector is essentially the distance from the valve core plate to the upper edge of the valve seat in a free state (or the depth the valve core plate is recessed relative to the valve seat). Therefore, it depends entirely on the machining control of the valve assembly and cannot be adjusted (However, if the armature lift is off-center, one can try using 1500+ grit fine sandpaper to polish the end face of the valve core plate).

-

Effect on Injection Characteristics: The magnitude of the armature lift affects the fuel injection quantity at all points. The larger the armature lift, the greater the injection quantity. When there is a deviation in injection quantity, replacing the valve assembly with a different armature lift can change the fuel quantity.

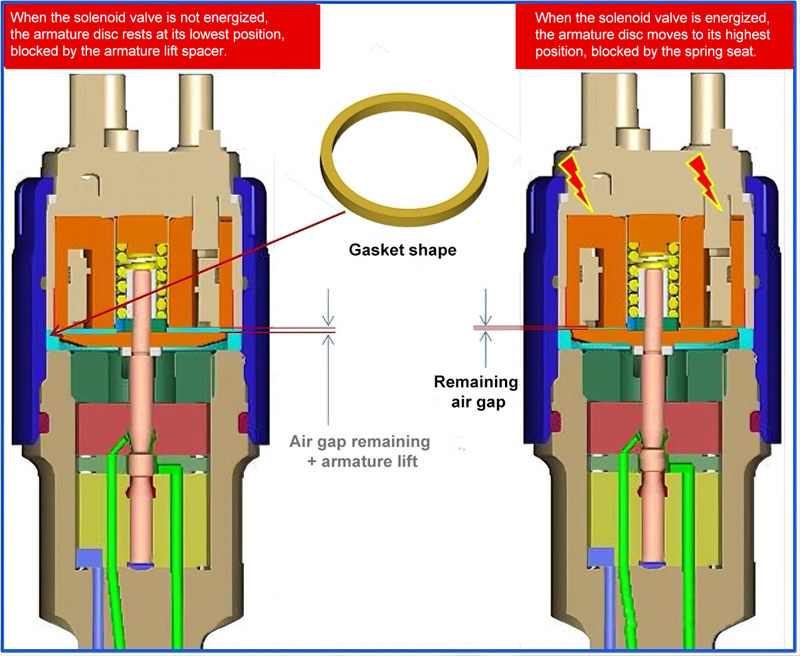

2. Air Gap

-

Definition: When the valve core plate (armature plate) moves to the uppermost position (the small step contacts the solenoid valve), the main body of the valve core plate does not contact the solenoid valve face but leaves a certain gap. This gap is the air gap.

-

Schematic:

-

Adjustment Trend: Like the armature lift, the air gap in Delphi injectors is controlled by the manufacturing of the valve assembly and cannot be adjusted.

-

Effect on Injection Characteristics:The larger the air gap, the smaller the injection quantity. However, the effect is not as significant as the armature lift.

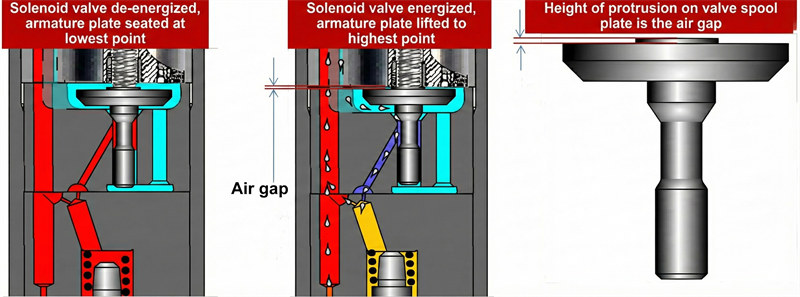

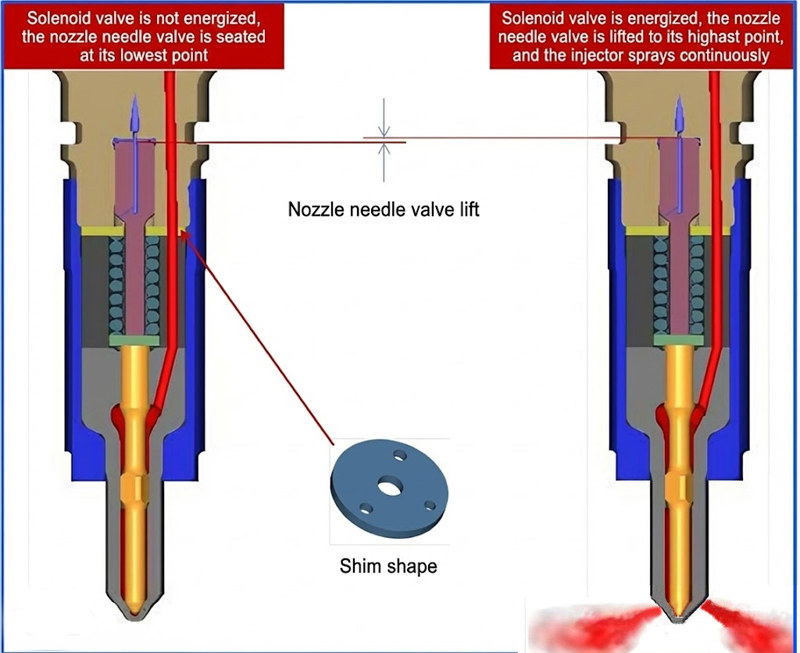

3. Needle Lift

-

Definition: The maximum displacement of the nozzle needle valve during injector operation is called the needle lift.

-

Schematic:

-

Adjustment Trend: The needle lift of Delphi injectors cannot be adjusted. Its size is determined jointly by the depth of the hole in the oil return spacer and the protrusion length of the needle valve.

-

Effect on Injection Characteristics:The larger the needle lift, the greater the injection quantity.

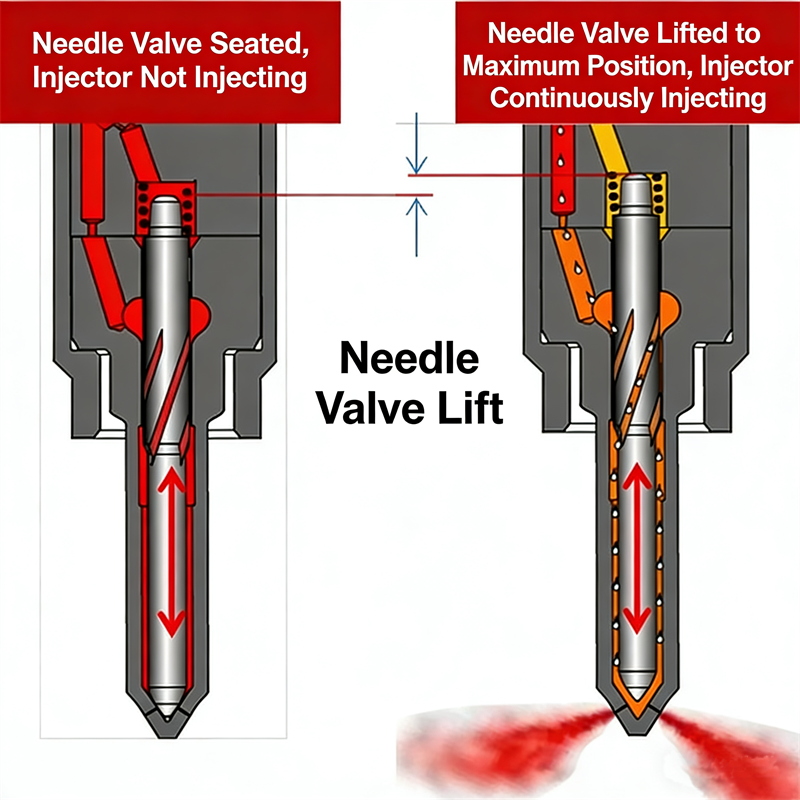

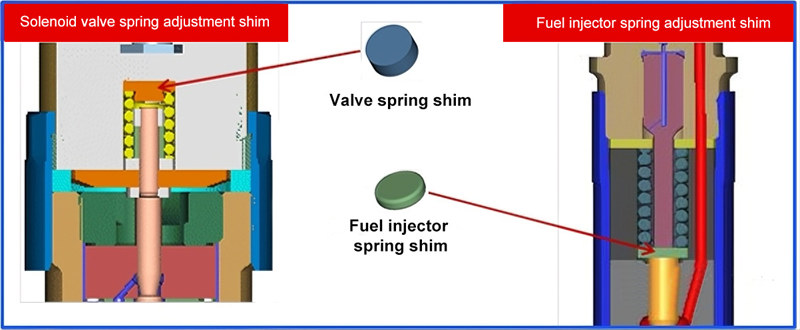

4. Solenoid Valve Spring Force

-

Definition: The solenoid valve spring has a preload force used to press the sealing ball tight to seal the high-pressure fuel in the valve seat control chamber. The force cannot be too small, otherwise high-pressure fuel will leak from the seat surface; nor can it be too large, otherwise the small ball will open slowly or not at all. The magnitude of the solenoid valve spring force can be adjusted by changing the thickness of the adjustment block.

-

Schematic:

-

Adjustment Trend:The longer (thicker) the adjustment block, the greater the solenoid valve spring force.

-

Effect on Injection Characteristics:The greater the solenoid valve spring force, the smaller the injection quantity (conversely, the smaller the force, the larger the injection quantity). The effect is particularly significant on the mid-speed fuel point.

5. Nozzle Spring Force

-

Definition: The nozzle spring has a preload force used to press the needle valve tight to seal the injection hole and prevent fuel injection. The force cannot be too small, otherwise fuel leakage will occur at the nozzle seat surface; nor can it be too large, otherwise the needle valve will open slowly. The Delphi injector nozzle spring preload is determined by the depth of the oil return spacer hole and does not need adjustment.

-

Schematic:[Refer to the image above.]

-

Adjustment Trend: The thicker the shim, the greater the spring preload.

II. CAT (Caterpillar) CR200 Common Rail Injectors

1. Armature Lift

-

Definition: The maximum distance the valve core can move during injector operation. The armature lift setting for CAT CR200 common rail injectors is generally between 35~45 microns. The armature lift of the CAT CR200 is adjusted by the adjustment disk sandwiched between the upper and lower valves.

-

Schematic:

-

Adjustment Trend:The thicker the adjustment disk, the larger the armature lift.

-

Effect on Injection Characteristics: The magnitude of the armature lift affects the injection quantity at all points. The larger the armature lift, the greater the injection quantity.

-

If the armature lift is too large or too small, the injection performance will become abnormal.

-

Too small causes a throttling effect; too large affects opening speed and easily causes cavitation.

-

Therefore, the prerequisite for adjusting fuel quantity via the shim is that the armature lift is within the effective range. Generally, when the armature lift is between 30~70 microns, the injector performance will not be abnormal.

-

2. Air Gap

-

Definition: When the armature plate moves to the uppermost position (stopped by the spring seat and spring inner liner), the armature plate does not contact the solenoid valve face but leaves a certain gap. This gap is the air gap. It is mainly used to avoid sticking (adhesion) between the armature plate and the solenoid valve.

-

When the solenoid is not energized, the armature plate sits on the seat under the action of the valve spring. At this time, the gap between the armature plate and the solenoid face is the sum of the armature lift and the air gap.

-

The air gap for CAT CR200 injectors is between 50~70 microns.

-

-

Schematic:

-

Adjustment Trend:The thicker the shim, the larger the air gap.

-

Effect on Injection Characteristics:The larger the air gap, the smaller the injection quantity.

3. Needle Lift

-

Definition: The maximum displacement of the nozzle needle valve during injector operation is called the needle lift.

-

Schematic:

-

Adjustment Trend:The thicker the shim, the larger the needle lift.

-

Effect on Injection Characteristics:The larger the needle lift, the greater the injection quantity, especially in the full load or high load regions.

4. Solenoid Valve Spring Force

-

Definition: The solenoid valve spring has a preload force used to press the sealing cone tight to seal the high-pressure fuel in the valve seat control chamber.

-

Cannot be too small, otherwise high-pressure fuel will leak from the seat surface.

-

Cannot be too large, otherwise the armature core will open slowly or not at all.

-

The magnitude of the solenoid valve spring force can be adjusted by changing the thickness of the valve spring shim.

-

-

Schematic:

-

Adjustment Trend:The thicker the shim, the greater the solenoid valve spring force.

-

Effect on Injection Characteristics:The greater the solenoid valve spring force, the smaller the injection quantity. The effect is particularly significant on the mid-speed fuel point.

5. Nozzle Spring Force

-

Definition: The nozzle spring has a preload force used to press the needle valve tight to seal the injection hole and prevent fuel injection.

-

Cannot be too small, otherwise fuel leakage will occur at the nozzle seat surface.

-

Cannot be too large, otherwise the needle valve will open slowly.

-

Note on source text: The source mentions "Delphi" here, which is likely a typo and should refer to CAT or general principles. The source notes that for CAT CR200, this can usually be adjusted via shims.

-

-

Schematic:[Refer to the images above.]

-

Adjustment Trend:The thicker the shim, the greater the spring preload.

-

Effect on Injection Characteristics:The greater the spring force, the smaller the injection quantity.

Related products

Language

Language