Beacon Machine Manufacturing Co.,ltd

Beacon CR819S All-Function Common Rail Injector, Pump, EUI/EUP & HEUI Test Bench

Need a complete diesel repair solution? The CR819S Test Bench handles Common Rail injectors/pumps, EUI/EUP, and HEUI systems with OEM precision. Features 15,000+ standard data points, injector coding, and remote updates. Boost your workshop's efficiency today.

Introduction

Overview:

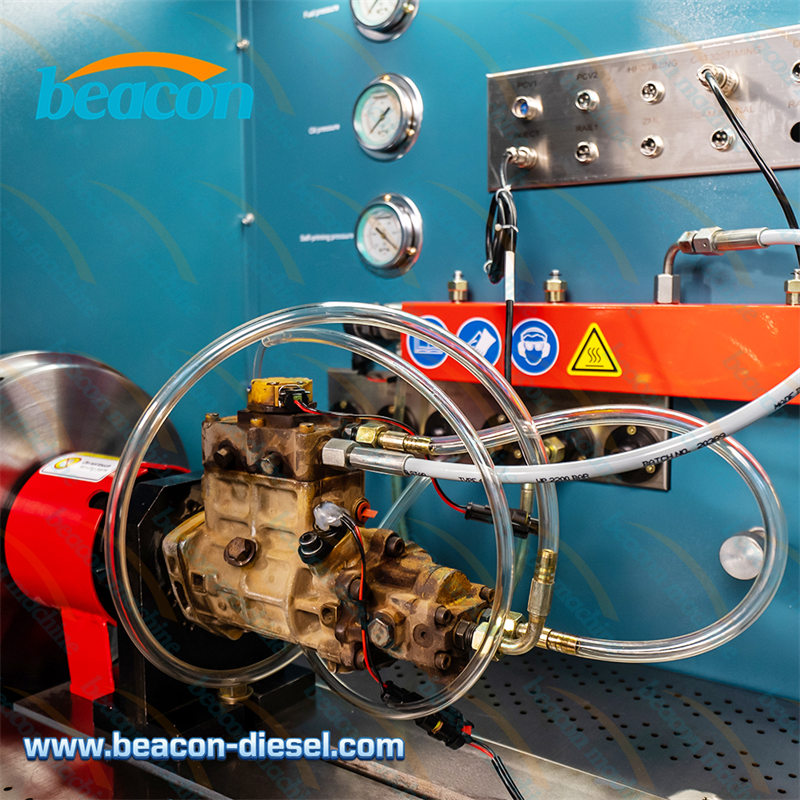

The CR819S is a flagship multi-function test bench designed to simulate the exact working conditions of a diesel engine ECU. It empowers maintenance workshops to diagnose and repair high-pressure common rail systems (Bosch, Denso, Delphi, Siemens), EUI/EUP systems, and HEUI hydraulic actuation systems all in one unit. By consolidating multiple testing functions into a single 11KW-22KW machine, the CR819S reduces equipment footprint while maximizing service capabilities, allowing you to generate OEM-standard test reports and QR codes for your customers.Key Features & Functions:

-

Common Rail Injector Testing: Tests seal, pilot injection, full load, and idle for Bosch, Denso, Delphi, and Piezo injectors.

-

High-Pressure Pump Testing: Supports CP1, CP2, CP3, HP0, HP3, HP4, Jier, Delphi, and Denso pumps.

-

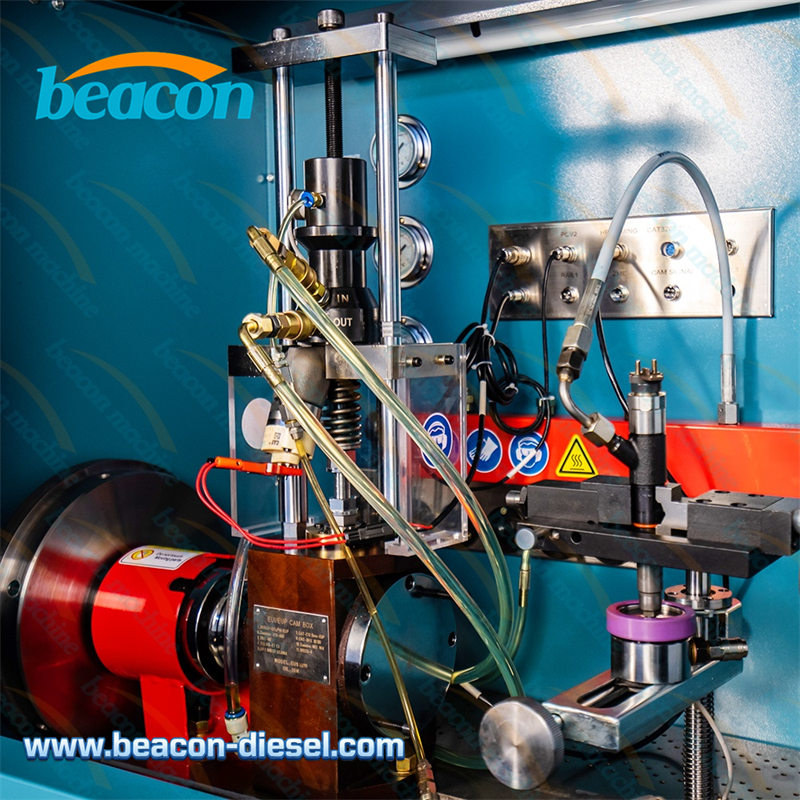

EUI/EUP Capabilities: Complete testing with TU-C, TU-D, and TU-E cam boxes (supports Bosch, Cummins, Detroit, CAT, etc.).

-

HEUI System Testing: Standard fixtures for CAT C7, C9, C-9, 3126B, 3412E, and Isuzu.

-

Specialized Pump Tests: Includes CAT 320D pump and Denso HP0 pump specific testing protocols.

-

Injector Coding: Generates Bosch IQA/IMA/ISA, Denso QR (16/22/24/30 pins), Delphi I2C/I3C, Siemens IIC, and Cummins XPI codes.

-

Optional Expansions: Compatible with Cummins PT injectors/pumps, HPI Q60/X15, AHE dynamic stroke measurement, and ZME metering units.

Integrated Control System:

The CR819S features a robust industrial PC control system supporting 15 languages. It comes pre-loaded with a massive database containing over 7,725 injector data points and 1,821 pump profiles, ensuring you can service virtually any vehicle that enters your shop. The system supports free remote upgrades, allowing you to stay current with new data without expensive hardware changes.

Comparison:

Looking for a different configuration? See how the CR819S compares to the CR708 Test Bench.parameter

| Parameter | Value |

| Model | CR819S |

| Main Motor Speed | 0 - 4000 r/min (Adjustable) |

| Motor Power Options | 11KW / 15KW / 18.5KW / 22KW |

| Power Supply | 380V/220V (3-Phase) or 220V (Single Phase) |

| Fuel Injector Voltage | 12V, 80V, 150V |

| Frequency Control | 0 - 1000 Hz |

| Injection Times | 0 - 1000 times |

| Pulse Width (Control) | 0 - 65535 μs |

| Fuel Pressure Control | 0 - 2400 bar |

| Pressure Accuracy | ± 1 bar |

| Flow Sensor Accuracy | 0.5% |

| Machine Dimension (LWH) | 178 * 115 * 156 cm |

| Packing Dimension | 185 * 120 * 170 cm |

| Net/Gross Weight | 740 KG / 800 KG |

*Test data from Beacon laboratory

Related products

Language

Language